- info@blemo.com

- 06106-8295-0

Frequency inverter - Explanation, function, structure

A frequency inverter is a technical device that generates a different AC voltage from the incoming AC voltage.

Frequency converters are used, for example, to control motor speeds (e.g. of an asynchronous motor or synchronous motor). If an electrical machine, such as a motor, were only operated via the public power grid, this would have some disadvantages in practice (see below). The current from the public grid often means that only certain speeds can be achieved with the machine used. In addition, disturbance variables such as harmonics or fluctuations in the grid can have a negative impact on the downstream process.

The frequency inverter also enables the motor to ramp up and down smoothly. The frequency inverter is therefore a controller for a drive with a variably adjustable frequency that regulates the machine (e.g. the motor speed) via parameters such as the frequency. In this way, motors and electrical machines can be controlled very precisely in industry. This is particularly important when industrial process requirements need to be met precisely.

Precise speed control also helps to save energy during operation, as the machines being operated work more efficiently. From the point of view of industrial requirements, it is particularly important that the frequency inverter works reliably and is robust. Many processes in industry, in manufacturing or even in individual companies depend on precisely adjustable parameterization of an electrical machine. With the frequency inverter, precisely these parameters can be set and programmed exactly according to the respective process requirements.

The setting options are versatile and range from setting speeds and safety functions to monitoring the system.

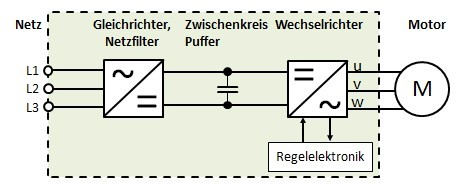

The basic structure of a frequency inverter consists of a rectifier, which usually feeds an intermediate circuit (there are also models without an intermediate circuit), an inverter, control electronics and a control circuit. The tasks of the rectifier are to stabilize and smooth the downstream intermediate circuit.

A capacitor is installed in the intermediate circuit to “smooth” the voltage. Several inverters can be installed on the DC link at the same time. Rectification is important in order to be able to use the incoming AC voltage from the power grid without interference (e.g. in the amplitude). A bridge circuit, for example, is installed in the rectifier for this purpose.

This is followed by an intermediate circuit with a buffer, which is smoothed by the so-called “buffer capacitor”. Depending on the design, there is sometimes also a coil here in order to be able to throttle particularly intense fluctuations in the current. The inverter circuit converts the smoothed voltage of the intermediate circuit into a three-phase alternating voltage.

The system parameters are monitored in the subsequent control circuit. There is a motor at the output of the frequency inverter circuit. A current flows through it, which has been transformed accordingly by the inverter. As unwanted voltage peaks can occur in the current, high-frequency pulse controllers are used to keep these as low as possible. Control electronics are used to convert a specific speed or torque by controlling the current

The tasks and function of a frequency inverter are varied depending on the model, for example the “frequency inverter 400v” or “frequency inverter 230v“, and differ, for example, according to the input voltage or the wiring.

The basic task of the frequency inverter in industry is to save energy by improving the efficiency of technical systems. Furthermore, it is used to adapt control variables such as the speed to specific process requirements or to adapt and regulate the power or torque of a drive according to the specifications of the process requirements.

The frequency inverter helps to improve the working environment by generally reducing the noise level (compared to other technical systems) of fans or pumps. In addition, frequency inverters 400v or frequency inverters 230v help to extend the service life of machines by reducing the mechanical load (e.g. through the smooth run-up of the motor).

The speed control of three-phase motors or a motor in drive technology can be regulated precisely and easily by a frequency inverter by converting electrical variables such as frequencies or AC voltage. This means that frequency inverters can be integrated almost seamlessly into any existing process in which peak loads need to be reduced or speeds precisely adjusted. By reducing the peak load, expensive peak demand prices are also avoided, which means that the required size of the motor can be reduced.

As already known, a frequency inverter is usually connected upstream of a motor. This generates a variable alternating voltage that is independent of the mains supply in terms of frequency and voltage level. This means that the output frequency and output voltage can be regulated.

As already mentioned, the advantage is the infinitely variable control of the speed range. The speed range can be regulated from approximately zero to the desired nominal speed, while the torque of the motor remains unchanged. A frequency inverter also enables the direction of rotation of the motor to be changed directly, for example via a control command. In three-phase machines, the direction of rotation is changed by changing the phase sequence.

Frequency converters are ideal for use in electric railroads. When supplying 50 Hz railroads from the national grid, there is often interference when using conventional single-phase transformer transformers, which can be avoided with frequency converters. The use of a converter also saves energy. On closer inspection, the investment costs are also quickly amortized.

Pump and fan applications account for around 70 percent of global applications for frequency inverters. This is due to the fact that a frequency inverter is particularly advantageous in this area, as the speeds required for fans and pumps can be set very precisely with this device. Pumps and fans are often integrated into highly complex and industrial processes that require very precise control. Frequency inverters are ideal for this, as they idealize the mains voltage for the respective application and the control of the downstream consumer.

Frequency inverters are also used successfully in lifting and transport applications such as conveyor technology, elevator technology, escalators, conveyor belts and other applications in this field. A precise control variable (e.g. a torque or speed) is particularly important for smoothly starting processes (e.g. an elevator) or precise control in a lifting application.

Servo inverters are used successfully in the field of servo technology. In the case of a servo drive or servo motor, the servo inverter supplies it with power. This enables the drive to move. These often require highly dynamic control of the current and are used in combination with power electronics. This enables precise and dynamic control of the speed and position of the drive.

There are many different types of frequency inverters on the market. Due to their widespread use in industry, especially in the control of pumps, compressors and fans, many different models have become established in the industry. As explained in the operating principle, one distinguishing feature of frequency inverters is the method of voltage and frequency control.

Another feature is the technology for reducing vibrations (e.g. harmonics). Frequency inverters can be single-phase and three-phase. The three most important methods for generating variable frequencies in frequency inverters are the:

Pulse width modulation or PWM technology is one of the best-known methods of control engineering. It is explained in the next section.

Pulse width modulation is a technique in which an electrical variable such as voltage alternates between two defined values. A so-called square-wave pulse is modulated at a constant frequency, i.e. a variable that always alternates exactly between two values. The method is also used, for example, in the control of energy conversion in a technical system.

PWM technology requires (bipolar) transistors (so-called “IGBT transistors”) for the alternating direction (power electronics) of the frequency converter, which generate the correct voltage level by constantly switching on and off. The width of the resulting pulses can be changed, thus pulse width modulation changes the output voltage and frequency. The signal modulated by this method always has a fixed amplitude, which makes the modulation suitable for very precise applications.

A power source inverter is a power converter that produces an AC voltage from a DC voltage. It is often simply referred to as an “inverter”.

As soon as a load is connected to the generated alternating voltage, an alternating current is generated from the direct current of the input voltage. The opposite of an inverter would be a rectifier, which turns an AC voltage at the input into a DC voltage.

A distinction is made between externally managed and self-managed inverters. Third-party inverters are able to feed electrical energy into an AC voltage grid. They work according to the phase specified by the power grid, i.e. synchronized with the grid. They adapt to the grid voltage. This type of inverter (externally fed) is used, for example, in a photovoltaic system. Direct current is generated there, which must first be converted into alternating current via an inverter and then fed into the public grid. Other examples can be found in the railroad and wind energy sectors.

With self-guided inverters, the phase is determined by the user. This has an effect on the amplitude of the AC voltage generated. These inverters are suitable for setting up stand-alone grids. For example, if a vacation home is not connected to the public grid, an inverter can generate AC voltage using batteries, for example. This can then be used in the house for electrical appliances, for example. This type of inverter (self-powered) is also used in battery-operated emergency power systems.

A voltage source inverter functions in the same way as the aforementioned current source inverter, but is intended for a different application. The voltage source inverter is used, for example, when a household appliance is designed for a supply voltage of 230 volts and 50 Hz and a 660 volt power grid is available on site, for example. The voltage source inverter or “inverter” is able to throttle this voltage according to the process specifications and make it usable for the connected consumers.

This section explains the operating modes and control options for frequency inverters. These provide an overview and help to make the right choice for the respective application.

V/f operation with frequency inverters is an efficient and simple method of controlling three-phase drives or three-phase machines with frequency inverters. First, a so-called control characteristic curve is defined based on the power data (e.g. 50 Hertz, 400 V nominal voltage) of the drive to be controlled. The motor is always driven to a specific nominal operating point if the frequency is changed in the same ratio. For example, at half the frequency, only half the voltage is applied to the motor.

If all frequencies are scanned, a straight line is created that connects the nominal operating point (e.g. 400 volts and 50 hertz) with the zero point. This means that the relationship between the frequency “f” and the voltage “U” always remains constant, regardless of the motor’s operating point. In “V/f operation”, the ratio of “voltage to frequency” is therefore constant. As a result, the speed of the motor varies depending on its load.

Compared to direct current control, field-oriented control, also known as “vector control”, enables greater utilization of the voltage while simultaneously reducing current losses (for the same power). This means that the field-oriented control method is more efficient than direct current control methods, for example.

Field-oriented control or vector control is a control method in which sinusoidal variables (or at least variables that are assumed to be largely sinusoidal) such as alternating voltage or alternating current are controlled by a specific phase angle within a period. This means that the instantaneous value is not regulated by the instantaneous value when viewed over time. The variables are transmitted in a rotating coordinate system for this purpose. Within the rotating coordinate system, this results in so-called constant values from the alternating variables, which can be applied to all methods known from control engineering.

In practice, a speed controller is based on a current controller that regulates the instantaneous current components (e.g. reactive and active current). During control, the motor parameters are determined, stored and adapted in an inverter, in some cases independently. The advantage: Separate speed measurement (and feedback) for speed and torque is no longer required.

Furthermore, the motor current fed back can be used as a control variable to determine the above-mentioned phase relationship to the voltage and, as a result, the necessary states of the motor (e.g. slip, speed, torque, thermal power loss).

Commutation is another type of motor control. Commutators are primarily used in brushless DC machines. A distinction is made between different types of commutation:

The differences lie partly in the type of energization; for example, with block commutation, exactly 2 out of 3 windings of the three-phase machine are always energized. The third three-phase winding is used by frequency converters (depending on the model) to measure the rotor voltage. This determines the current position angle of the rotor. The advantage: Permanently excited machines can thus be commutated by frequency inverters without using additional sensors (e.g. absolute encoders).

Sinusoidal commutation is usually used for the operation of asynchronous machines, which is used by frequency inverters (e.g. sinusoidal modulation of the pulse widths). Various switching states of the phases are possible, which are not discussed in detail here.

Another option for frequency inverters is optimization by superimposing harmonics. Ideally and in theory, an AC voltage always follows a perfect sinusoidal curve. In theory, the polarity of the sine wave alternates evenly between positive and negative values. However, such a uniform curve is virtually impossible in technology. In practice, the superimposition of several sine waves is almost unavoidable due to several operating resources.

The so-called harmonics can have several causes. On the one hand, equipment that has a non-linear characteristic (see above) (e.g. transformers or power electronics modules) can promote current consumption that distorts the “ideal” sinusoidal voltage and thus leads to harmonics. Switch-mode power supplies that cause non-sinusoidal currents (e.g. televisions, computers or lighting) can also disturb a linear current consumption and thus trigger harmonics. Harmonics are therefore problematic as they can have a negative effect on the equipment. They can lead to functional impairments or even destroy the affected devices. The following technical restrictions can be caused by harmonics:

The list could be continued at this point, but for now it includes a rough overview of the effects of harmonics on technical systems and installations. In today’s world, in which technical devices and systems are increasingly being pushed to their performance limits, the effect of harmonics is particularly important. Reducing them helps to optimize processes and operate machines and systems more effectively.

There are high technical requirements to minimize harmonics (e.g. the EN61000-3-2 standard). In summary, it can be said that the use of a frequency inverter can increase the performance of a drive by around 15 percent.

Around 75 percent of global applications for frequency inverters are for controlling pumps, compressors or fans. These are very common in industry, which is why frequency inverters are a major focus.

The frequency inverter offers many advantages in use. For example, it can regulate or vary the power output depending on the energy requirements of the driven device. In this way, it helps to save energy during operation and even optimize energy consumption.

Compared to direct operation on the mains, the motor runs at full load depending on demand instead of always running at full load regardless of demand. Depending on the application, this usually results in electricity savings of up to 70 percent. The so-called “roll-on effect” of a frequency inverter even reduces the nitrogen oxide emissions of the overall system and also improves the CO₂ balance.

As a manufacturer of frequency inverters, BLEMO supplies high-quality frequency inverters that are tailored to the individual requirements of customers. For example, we offer 400v frequency inverters and 230v frequency inverters. Each inverter is thoroughly tested in the factory shortly before delivery. The experts at BLEMO concentrate on the details of drive optimization. BLEMO is characterized by always being at the cutting edge of technology and high-quality new developments.

BLEMO’s range of soft starters and frequency inverters is particularly broad. With extensive access to know-how and various application and maintenance services, you will always receive perfect support for all aspects of frequency inverters. This ensures that your systems run optimally at all times.

Another important factor for flexibility is the fact that you can use your frequency inverters with standard motor technologies. This enables great savings in terms of spare parts, especially when it comes to repairs or retrofitting. BLEMO – quality from a single source, characterized above all by high-quality products and outstanding customer service.

Here you will find a rough overview of questions and answers on the subject of frequency inverters. We will be happy to advise you in detail on the subject.

This depends on the type of machine you want to operate, for example AC motors, synchronous motors, asynchronous motors or three-phase motors.

This depends on your local conditions (AC voltage 230v or three-phase AC voltage 400v) and the process as well as the machines you wish to operate. It is best to ask our experts about this.

The frequency inverter converts an input voltage (e.g. alternating current) into a directional voltage that is suitable for precise industrial applications.

Whenever you want to precisely control a motor that would otherwise be connected directly to the mains. For example, around 70 percent of frequency inverter applications are for controlling fans, compressors or pumps.

It depends on the application. Most motors work with a frequency inverter without any problems. It is best to ask our experts which frequency inverter you need.

Frequency inverters brake with a so-called “brake chopper”, for example. This conducts excess energy from an intermediate circuit into a braking resistor. There it is converted into heat. Otherwise, the DC link voltage would rise and destroy components such as capacitors.

There isn’t one. All these names refer to the same device.